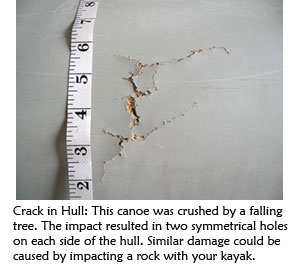

Imagine that you’re paddling your fiberglass kayak on a long trip in a remote area. On your way in through the surf, the bottom of your boat meets with an unseen rock—Wham! One minute you’re paddling a seaworthy boat, the next you’re taking on water. You’re miles from your car, and something needs to be done to keep the water out. A hasty patch of duct tape might do the trick for a while, but for a durable and reliable repair, there’s only one solution—polyester resin and fiberglass.

Resin needs a warm environment to cure in, so if you’re traveling in cold weather, you may wonder how you’ll get the resin to harden. Adding a little outside heat is the answer. Armed with a hydration bag full of hot water, you can put a solid patch onto the hull of your boat, even in adverse conditions.

You needn’t be intimidated by the prospect of working with fiberglass. Rudimentary fiberglass work is straightforward and easy to do. The polyester resin you’ll use for repairs is fairly tolerant of imprecise mixing and variable temperatures. It’s worth practicing with fiberglass a little bit at home to develop a familiarity with the process, but you don’t need to be an expert to make a quality repair.

Materials Compatibility

Polyester resin is easy to work with, but it’s not compatible with some other types of resins. What this means is that if your kayak was built with epoxy resin, polyester won’t stick to it. Your patch will pop off. Polyester resin will stick to hulls made with vinylester if you prep the surface with sandpaper very aggressively, but it still isn’t as safe a bet as polyester repairs on polyester kayaks.

The good news is that virtually all fiberglass kayaks use polyester resin in their construction. If you have a Kevlar or carbon-fiber kayak, it’s more likely that one of the other resin types was used. Check with the manufacturer of your boat to determine its resin type. Polyester won’t stick to epoxy, so repairs to epoxy or vinylester hulls should be made using marine epoxy resins. (This type of repair falls outside the scope of this article.)

Epoxy will stick to polyester, but if you need to make subsequent repairs in the same area with polyester or want to restore the gel-coat, the epoxy must be removed. Epoxy requires precise mixing to ensure a proper cure and is usually slower to cure than polyester resin. All of these things make epoxy resins ill-suited for use in field repairs for fiberglass kayaks.

Safety Precautions/Environmental Concerns

Polyester resin is not healthy stuff. Avoid getting it on your skin or breathing its vapors. You’re unlikely to be carrying a respirator in the field, but take whatever precautions you can when doing your repair. Wear latex or nitrile gloves from your first aid kit. Set up your workplace where there’s a breeze, and stay upwind of the vapors. The materials are also toxic to the environment, so pack out any waste from the fiberglass repair process, regardless of how small it is. Never burn your fiberglass waste—if you pack it in, pack it out.

Polyester resin is not healthy stuff. Avoid getting it on your skin or breathing its vapors. You’re unlikely to be carrying a respirator in the field, but take whatever precautions you can when doing your repair. Wear latex or nitrile gloves from your first aid kit. Set up your workplace where there’s a breeze, and stay upwind of the vapors. The materials are also toxic to the environment, so pack out any waste from the fiberglass repair process, regardless of how small it is. Never burn your fiberglass waste—if you pack it in, pack it out.

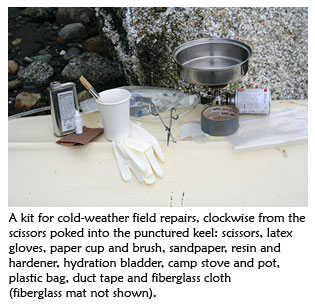

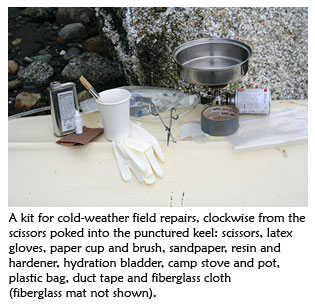

Repair Kit

The materials for a fiberglass field-repair kit can be found at your local hardware store and supermarket. Polyester resin usually comes in metal cans that are quart sized or larger—more resin than you’ll want to take on most trips. You’ll want to take a smaller amount, but small metal canisters are hard to find, and the polyester will melt most plastics. At many marine and auto supply stores, you’ll find a Bondo fiberglass repair kit. It comes with eight ounces of waxed resin—enough for a basic field-repair kit—in a bottle made of a special resin-resistant plastic. The kit also includes hardener and woven fiberglass cloth. Chopped-strand fiberglass mat can often be found near the kits or at the hardware store.

I use a half-gallon, wide-mouth Nalgene bottle as a materials container for my repair kit. These bottles will fit behind the seat of many kayaks, and they are absolutely watertight, so they’ll keep items like sandpaper from getting damp.

Surface Preparation

The damaged area of your kayak has to be dry and free of salt residue to get a patch to stick. This means getting out of the rain and under a tarp if you’re traveling in wet conditions. If possible, rinse the damaged area with fresh water. Dry the boat thoroughly inside and out. This can be a real challenge in some conditions. You might have to add heat to the boat to help the drying process.  You don’t want to risk burning the kayak by using the flames of a stove or campfire, so the safest way to do this is with a hydration bag filled with hot water.

You don’t want to risk burning the kayak by using the flames of a stove or campfire, so the safest way to do this is with a hydration bag filled with hot water.

Use your camp stove to heat a couple liters of water. Seawater will work fine if fresh water is scarce—just remember to rinse the bag before using it for drinking water again. Pour the water into the hydration bag once it’s hot to the touch but not boiling. Both MSR Dromedary Bags and Cascade Designs Platypus bladders are approved to hold hot liquids. Both are also available with wide openings for easy filling. Use care when transferring the hot liquid so that you don’t scald yourself! Set the bag inside the hull in the area to be dried.

Once the kayak is dry and clean, you’ll need to sand the inside of the hull where the patch is to be applied. You want a rough surface for good adhesion, so use 50-grit paper and be aggressive. Make sure that you sand an area that’s larger than the patch you intend to apply. After sanding, blow or wipe the resulting dust out of the way. In a more controlled environment, you would wipe the site of the repair with acetone or denatured alcohol, but there’s really no need to go to the trouble of carrying these solvents in your field-repair kit.

You’ll be applying duct tape to the hull of the boat in the next step, but you may find that your tape won’t stick to a cold surface. The hydration bladder full of hot water again comes in handy. You can warm the boat by placing the bag on the damaged area. Try not to get the outside of the hydration bladder wet, and avoid getting water on the hull of your boat. Your kayak needs to be dry for the repair to cure properly.

Leave the bag in place long enough to warm the kayak’s hull. The elapsed time will vary depending on the outside temperature. You can throw a sleeping bag or fleece sweater over the hull and water bag to speed the process. It also helps to heat up the duct tape to make it stickier, so put it inside your clothing layers or on top of the water bag. Do the same with your bottle of polyester resin. In cold temperatures, resin becomes more viscous and more difficult to paint onto a patch. Once the hull and tape are warm enough to stick, remove the bladder and wrap it in the sleeping bag or sweater to keep it from cooling rapidly.

Use the tape to apply a piece of plastic (cutting up a large Ziploc bag works well) to the outside of the hull over the area to be patched. The plastic is to keep resin from seeping through the damaged area of the hull. Make sure that the plastic covers the repair area and overlaps out onto the undamaged portion of the hull.

Turn the kayak so that the area to be repaired is down—you’ll avoid having resin run across the hull. You may need to use some ingenuity to get the kayak to stay in this position. Consider digging a hole in the beach across which you can set the boat, or propping it up on driftwood or boulders. You don’t want the kayak resting on the area you’ll be repairing since that would cause a flat spot in the boat. As you position the kayak, you may want to wrap a layer of insulation around the outside of the hull in the area of the repair. A sleeping mat, fleece sweater or sleeping bag can be used to insulate the hull and keep the patch warm.

Applying the Patch

Cut a piece of chopped-strand fiberglass mat that is slightly larger than the area to be repaired. Mat is excellent for repairs because it holds a large amount of resin. A high resin-to-glass ratio is considered bad form in kayak manufacturing, but it works well for making a stiff, waterproof patch in the field. Cut a second piece of mat that’s about a half-inch larger than the first. If you’re repairing a large hole or tear, a third patch of woven fiberglass cloth, cut slightly larger than the second patch, will improve the strength of a patch.

Put on a pair of protective gloves and mix up your resin. Follow the directions printed on the resin or catalyst. These typically call for 15 drops of catalyst/hardener for each ounce of resin, which is a ratio approaching two-percent catalyst. This ratio is a good one for field repairs. Waxed resin has a wax additive that rises to the surface of the repair as it cures. This wax creates an oxygen barrier that makes the resin cure with a hard, dry surface. Using unwaxed resin may result in a sticky patch.

Mix up enough resin to complete the repair. Three or four ounces should do the job for a small patch. You’ll need a container to mix it in. I put several eight-ounce paper cups into my repair kit for mixing. These are the same cups that you would find at a coffee shop, convenience store or grocery store. Both waxed and unwaxed cups will work. If you packed a stirring stick, great; if not, use a smooth stick from the beach.

Set a Ziploc-type plastic bag on a flat and firm surface, and begin “wetting out” your patches. Paint a little resin onto the bag, then lay one of the precut pieces of glass mat onto that resin. Use your paintbrush to work the resin into the glass fabric until it becomes translucent. You’ll have to add more resin as you work to get the patch completely wetted out. Follow this process for each of your patches. Working with the resin will be much easier if you have prewarmed it by tucking it in with the hot water bag. If the resin is cold and super-thick, you can still complete the repair, it will just be a little harder to work the resin into the glass patches.

Once your patches are wetted out, paint a layer of resin onto the inside of the hull where the patches will be applied. Place the smallest patch onto this area, and paint it with additional resin to make sure that it’s fully saturated and adhered to the hull. Use the brush to work any air bubbles out of the patch. Repeat the process with the second patch and the woven glass if you have chosen to use it. Once you’re satisfied that the complete patch is fully saturated, cover the repair with the plastic bag that you used for wetting-out—sticky side down.

If you’ve worked quickly, your hot water bag will still be warm. If the water has cooled too far, pour it into a cook pot, reheat it to lukewarm and fill the bladder again. Even on a cold day, you shouldn’t use a bag that is hot to the touch—if you do, your resin will cure too quickly and may develop cracks. Water near your body temperature will be warm enough to do the job.

If you’ve worked quickly, your hot water bag will still be warm. If the water has cooled too far, pour it into a cook pot, reheat it to lukewarm and fill the bladder again. Even on a cold day, you shouldn’t use a bag that is hot to the touch—if you do, your resin will cure too quickly and may develop cracks. Water near your body temperature will be warm enough to do the job.

Put the water bag inside the kayak over the patch, and sit back to wait. The plastic on the inside of the hull should keep the resin from contacting the hydration bladder. Cover the bag with a fleece sweater or sleeping bag to help contain the heat. If the hull and bag are insulated, this technique will cause the polyester resin to cure even with air temperatures near freezing.

While you’re waiting, clean up your work site and double-bag the fiberglass waste. Monitor the hardening process by putting your hand on the hull near the repair. It should not be hot to the touch. If the patch is giving off too much heat, remove the hot water bag and let the repair continue to cure on its own, insulating it with the fleece sweater again. Give the patch 20 minutes to cure, and take a peek. Remove the hydration bladder and peel up the plastic. If the patch is hard and dry, you’re done. If it’s still sticky, add more heat. Reheat the water if you need to.

Once the patch is fully hardened, you can remove the covering layers from both the inside and the outside. The outer patch may be a bit rough due to seeping of resin underneath the plastic. Use some coarse sandpaper to take down any major bumps. Don’t worry about cosmetics—you can do a nice gel-coat repair when you get home (see “Gel-Coat Repair for Mortals,” by Brian Day, SK, Feb. ’06). Make sure that the patch is smooth enough on the inside that it won’t damage your dry bags. Sand the inner patch to take down any rough spots if necessary. Pack away the last of your waste materials and relax—you’re back in the paddling business.

Special Situations

Certain areas of a kayak’s hull may be difficult to reach for internal patching. The most obvious spots are underneath the seat and at the extreme ends of the hull or near bulkheads. In these spots, it’s probably best to apply your patch to the outside of the hull. You’ll also have to apply heat from the outside, and you may have difficulty backing the patch with a piece of plastic. The resulting repair will be cosmetically unattractive, but structurally sound. Proper repairs can be completed at home or by a professional fiberglass repair shop.

Practice Makes Perfect

Field repairs on fiberglass kayaks are easy to do if you have the right materials and know the right tricks. A bit of practice with fiberglass materials will improve your results when it counts and boost your confidence—and even cold-weather repairs are possible if you apply a little heat to the job. Take the time to put together a basic fiberglass repair kit and learn how to use it. One day, it might help you or a paddling partner make it home.

Sequence of Repair

1 Heat water, fill hydration bladder

2 Clean, dry and prep hull

3 Warm tape, resin and hull

4 Tape plastic to hull

5 Cut out patches

6 Mix resin

7 Wet out patches

8 Apply patches to inside of hull

9 Cover with plastic and water bladder

10 Wait 20 minutes

11 Remove plastic, sand inside and outside of hull

Fiberglass Repair Kit Contents

Waxed Polyester Resin

Catalyst

Fiberglass Mat

Fiberglass Cloth

Disposable Paint Brushes

Stirring Sticks

Paper Cups

Plastic Sheet or Freezer Bags (1-gallon size)*

Duct Tape*

Small Scissors*

50-Grit Sandpaper

Latex or Nitrile Gloves*

Watertight Container

*These items need not be specific to your fiberglass repair kit. They might be a part of your first aid kit or general camping gear.